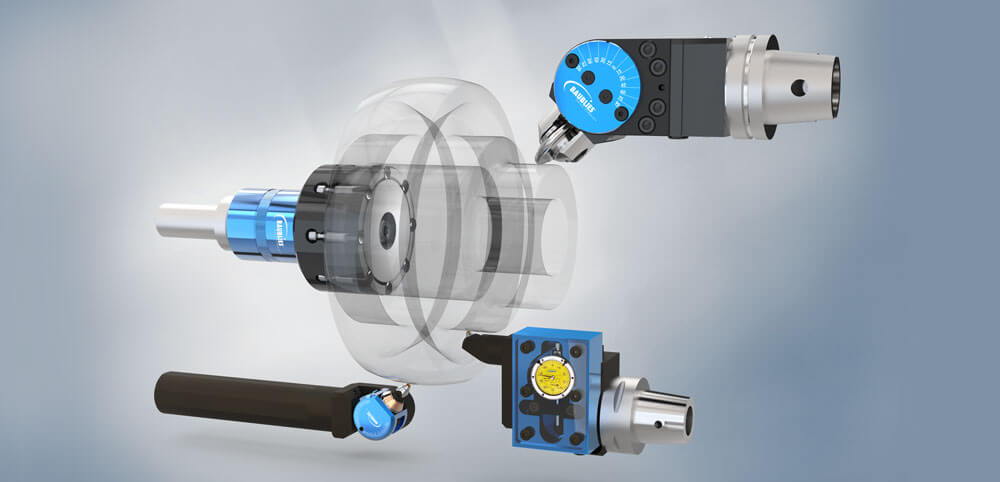

BAUBLIES:

Optimierung von Metall-Oberflächen durch Rollieren und Diamant-Glätten.

Optimierung von Metall-Oberflächen durch Rollieren und Diamant-Glätten.

Gewindefertigung durch spanlose und spanende Bearbeitung.

Welcome to the specialists for the optimization of metal surfaces

by roller burnishing and the experts for external thread production.

We are pleased to show you the first general catalogue of the Baublies Group.

Our catalogue has been designed to give you an overview of the extensive range of services offered by the Baublies Group. As well as detailed technical data, it contains information on the individual companies within the Baublies Group and provides valuable tips on the use and handling of our tool systems. In addition, our catalogue is also intended to serve as a guide to the various surface technologies..

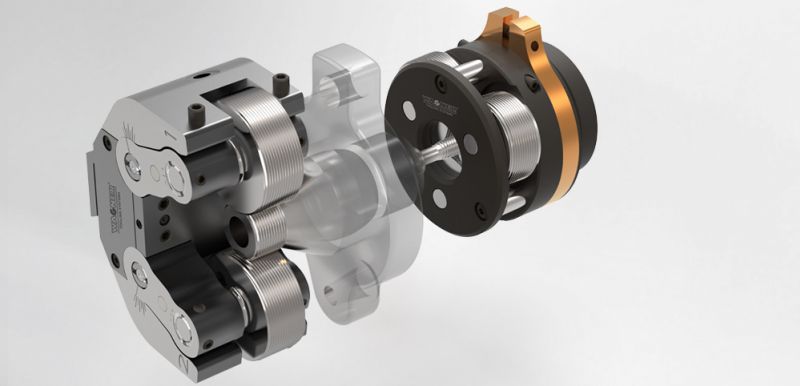

HELIX - THE EXPERT FOR AXIAL THREAD ROLLING

* accessories: rollers,

locking device, shank

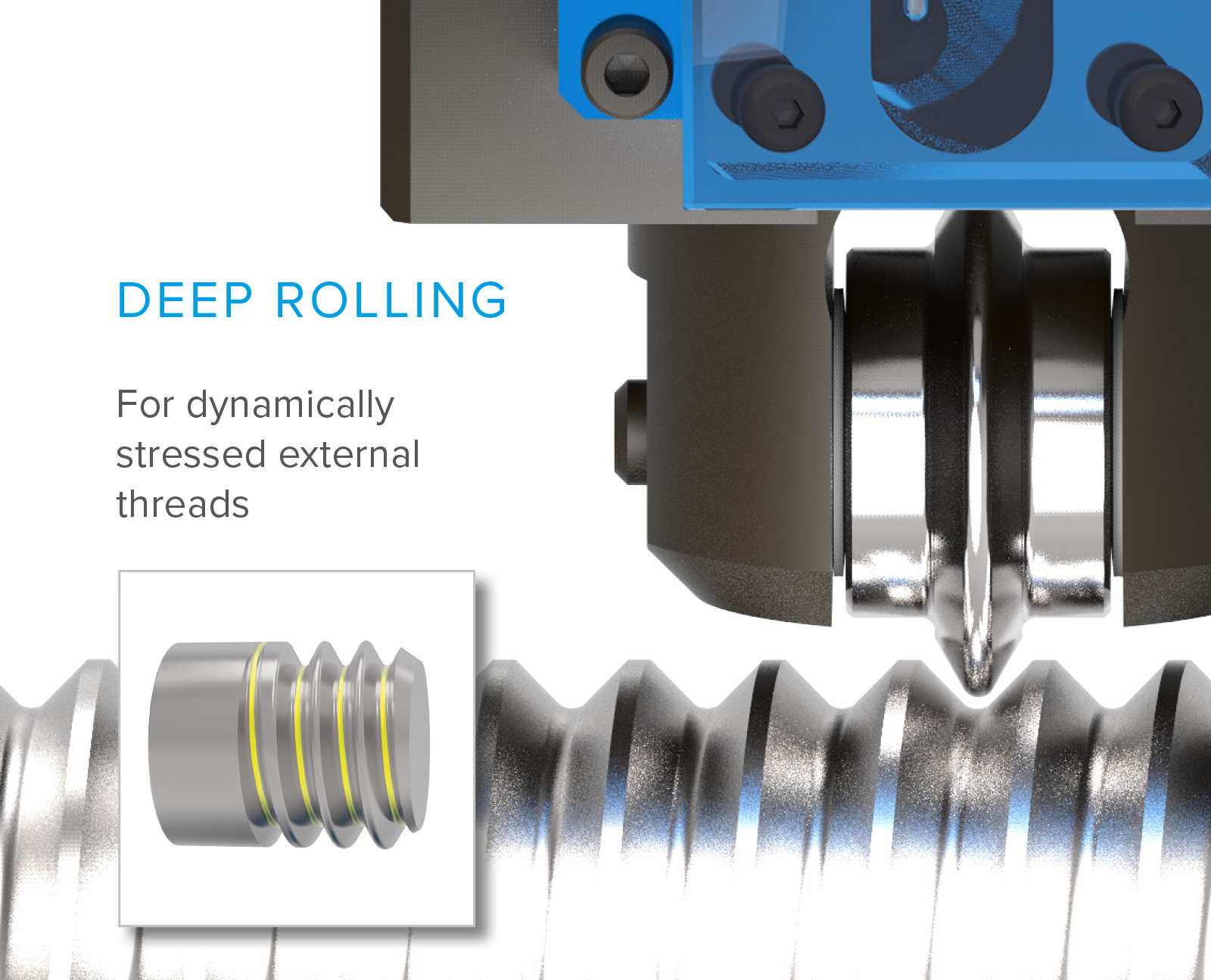

In the case of cut threads, the course of the grain of the workpiece is interrupted. With rolled threads, on the other hand, the grain flow is not interrupted, thus the surface of the thread is hardened and the workpiece is less sensitive to notch effects. With the Baublies single roller tool for deep rolling of radii on threads, an increase in the dynamic strength properties can be achieved. The tool rolls the core radius of an external thread and thus hardens the surface. The result is higher wear resistance and reduced notch sensitivity.

ADVANTAGES